Key Features

Real-Time End-to-End Production Visualization

MXP offers comprehensive, real-time visibility across your entire production lifecycle—including planned, current, and completed batches. Operators and managers can instantly visualize timelines, monitor equipment status, and track critical process parameters, enabling quicker decisions and reduced downtime.

Digitized Workflows for Enhanced Compliance

MXP digitizes batch records, work instructions, and logbooks, ensuring adherence to standard operating procedures (SOPs). By eliminating manual paper-based processes, MXP significantly reduces costly errors, enhances data integrity, and simplifies validation, ultimately improving regulatory compliance and process security.

Accelerated Batch Review and Release

Leveraging review-by-exception capabilities, MXP streamlines batch validation and reduces the number of manual operator interventions and signatures required. Real-time data visibility ensures batches consistently meet quality standards, enabling faster batch release and improved production throughput.

Comprehensive Batch Execution Summary

Gain a holistic summary of each batch execution, ensuring full transparency and enabling rapid identification of potential issues.

Why choose MXP?

MXP transforms manufacturing processes through comprehensive digital integration, unlocking operational efficiencies, enhancing quality assurance, and enabling proactive decision-making.

Equipment and Process Unit Tracking

Easily monitor equipment utilization, availability, and maintenance needs, optimizing resource allocation and productivity.

Recipe Authoring and Management

Intuitive tools for managing recipes streamline product formulation, validation, and execution, ensuring repeatable, high-quality manufacturing results.

Modular and Scalable Architecture

Designed for flexibility, MXP scales effortlessly from small facilities to large-scale, complex manufacturing operations. Its modular architecture allows your organization to adapt seamlessly to evolving production requirements, supporting continuous optimization and growth.

Production Orchestration

Efficiently coordinate production schedules and workflows, reducing downtime and enhancing overall productivity.

Process Monitoring and Alerts

Real-time monitoring capabilities promptly identify process anomalies, minimizing disruption through immediate alerts.

Drill-Down Reporting and Analysis

Detailed analytics allow users to pinpoint specific operational issues, track trends, and support continuous improvement initiatives.

Seamless Integration with Enterprise Systems

Effortlessly integrates with existing systems (MES, ERP, LIMS), providing cohesive data flow and operational visibility across your entire organization.

Real-Time Exception Identification

Rapid identification of exceptions accelerates resolution, ensuring sustained compliance and product quality.

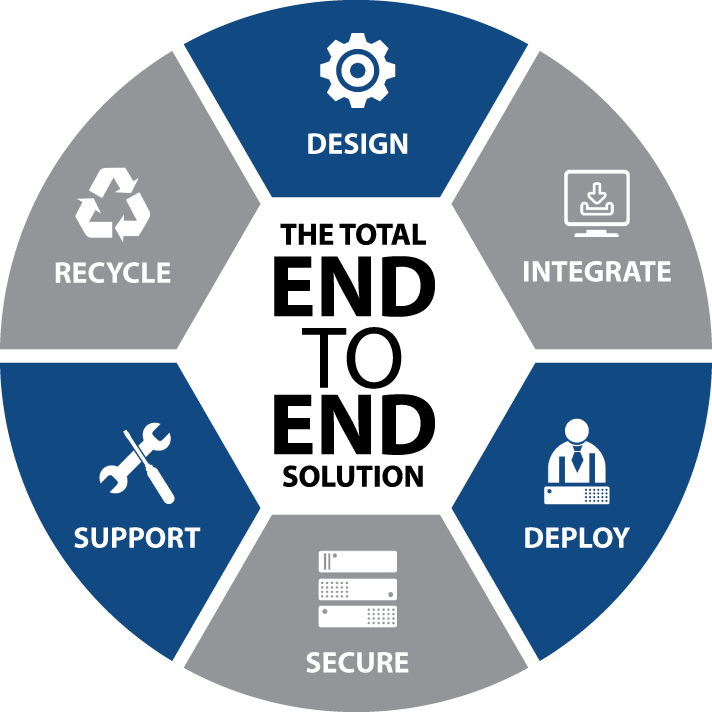

End-to-End Process Digitization

Complete digitization of manufacturing processes reduces complexity, enhances documentation accuracy, and ensures robust compliance.